Quality Policy

Our mission is not simply to be good at quality but to exceed customer’s expectations. If we are to convince and secure our customers in the long term, we must continue to take a lead on quality, technological progress, reliability and cost – effectiveness as well as ensuring correct, timely deliveries and providing committed service.

This has always been the foundation on which the success of the JMHSPL Hydraulics Pvt. Ltd. is based.

This standard we must aim for is quality in the eyes or our customers, we must focus every effort on satisfying the expectations and requirement of our customers. Every employee must think and act in accordance with this principal and we must all co-operatives with goal in mind.

Our work is based on the objective of ‘Zero defect’ and we implement measure in all departments to ensure defect prevention, not simply defect detention. The result of our work is free from defects, at all times and in every workplace of company. The management and employees of company give their wholehearted commitment to maintain this quality policy.

A modern quality management system is in place at all of JMHSPL manufacturing locations. Many years ago, we make a gradual transition from actions serving to detect to actions aimed at preventing defects. Quality management at JMHSPL is a dynamic process that is checked on a daily basis to ensure that continuous improvements are made. We are an ISO 9001-2015 company and all systems & procedures are strictly complied with. We believe that the quality and reliability of our finished JMHSPL products is directly related to the quality of the raw material going into them. Therefore, we begin our manufacturing process by selecting suppliers that can consistently meet our stringent material requirement. Only after material are tested and approved they are place in to JMHSPL inventory control system. To further insure that our products perform reliability each cylinder is functionally tested for 15-20 cycles and pressure tested at 1.5 times the normal working pressure then held for 5 minutes fully extended and contracted in both direction in our automated test accessories stand. This pressure test assures that the assembly process welds, joints and over all cylinder integrity is more than adequate. JMHSPL is committed to product quality and product excellence via our continues improvement ideology in our quality system and manufacturing. We stand behind JMHSPL Cylinder products with warranty of One year so you can rely on us totally

Quality Processes

JMHSPL Hydraulics Pvt. Ltd. has introduced a comprehensive quality program that is both flexible and though for our diverse range of cylinders. This protocol allows for many different sizes, styles and quantities of cylinders to flow through the systems, whilst still devoting the attention to detail necessary to consistently assure defect free finished product.

From Raw Material to Delivery

We begin the quality process by selecting and evaluating world-class supplier from countries like Italy, German, China and South Korea as the quality of raw material directly impacts the finished product. Upon arrival JMHSPL all raw material are thoroughly inspected by our quality assurance Team (QA) to ensure that metallurgical and dimension requirements are satisfied following which only satisfactory material is readied for processing. Throughout the various processing stages the raw material undergoes both dimensional and 100% visual inspection before moving to the assemble process.

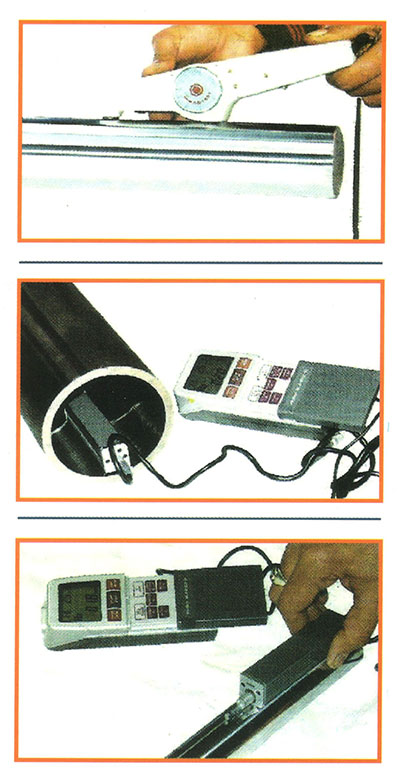

Once the material is certified for assembly QC technicians inspect the sub-assembled components for any assembly issue. Such as misalignments of components, improper torque of a fastener of weld defect. The sub-assembly inspection includes dimensional Inspection, 100% dye penetrate weld inspection, 100% visual inspection and torque.

After passing the preceding tests, all fully assembled cylinders moved to the hydraulic test unit. The tests or inspection that takes place included pressure testing for 5 minutes in both extended and retracted position. Visual inspection for leakage at all welds or joints, stroke measurement and complete dimensional measurements. Following these test, approved cylinder proceed to cleaning, coating and packaging. Once the Hydraulic cylinders are cleaned and coated, the final inspection occurs during packaging, where QC team members ensure that identification color and type of packaging are in compliance.

Continuous Improvement Philosophy

The quality system of JMHSPL not only incorporates standard metering practices, visual inspection and proprietary test equipment by also command a commitment philosophy. By monitoring and updating our quality system through employee and customer feedback, we produce cylinders and cylinders components to the highest quality. In furthering our commitment to excellence and continuous improvement, we encourage our potential customers or test our products along side our competitors.