WATER COOLED MOULDS

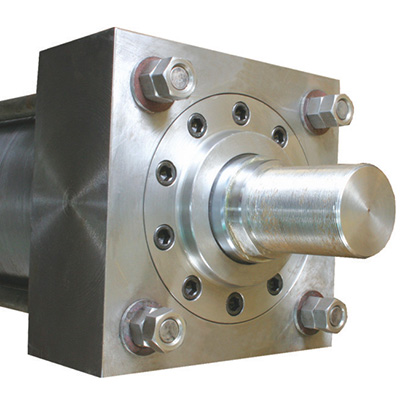

Cylindrical Water Cooled Moulds

The mould comprises of two parts – one is jacket and the other is the inside liner. Jacket is manufactured out of seamless cold-drawn cylindrical pipe of special steel and inner liner is made of heat resisting alloy steel. The Linner is fixed inside the jacket with uniform annular space for the flow of water to cool the liquid metal poured inside the liner from top. The inner-liner is replaceable after certain period of time while jacket useful life is ever lasting.

Semi-Continuous Moulds

It is congruence of Jacket & Spray system in one mould. Design is such that during the initial stage of solidification, cooling is done through jacketed water column and after certain length is cast, water is sprayed directly on the body of the billet prior to its ejection. Single length of Billet 3000mm.

Advantages of Water Cooled Moulds:

a) Dense and high quality surface finish, no machining of surface is needed.

b) Billets/Slabs can be taken out from the moulds in less than five minutes.

c) Number of moulds required for casting one heat of the metal is much less.

d) Minimum shrinkage cavity at the pouring end, which results in 5%less scrap generation.

Superior billets with semi continues casting machine for higher production.

Most suitable for copper forgings with high density and superior conductivity.

All Sizes are in MM

|

Diameter |

Length |

|

Ø 50 |

1000 |

|

Ø 76 |

1219 |

|

Ø 89 |

1321 |

|

Ø 102 |

1524 |

|

Ø 127 |

1676 |

|

Ø 152 |

1829 |

|

Ø 178 |

2083 |

|

Ø 203 |

2286 |

|

Ø 229 |

2438 |

|

Ø 254 |

2438 |

|

Ø 279 |

2438 |

|

Ø 305 |

2438 |