HARD CHROME PLATED PISTON ROD/BAR

|

Metric Size |

Dia 25mm to 250mm |

|

Standard Lengths |

3000mm to 10000mm Long |

|

Surface Hardness |

>HV-900-1150 |

|

Surface smoothness |

Ra 0.2 Microns or Better |

|

Surface Finish |

Surface shall be free of dent or Scratches |

|

Roundness |

Out of Roundness is max 1/3 of Diameter tolerance |

|

Chrome Thickness |

25 Microns Min. |

|

Tolerance |

ISO f7, f8 |

|

Circularity |

According to ISO f7, f8 |

|

Straightness |

0.1/1000 |

|

Corrosion Resistance |

Rating 10 Achieved after 120 hrs in neutral salt spray |

|

Packing |

Wrap in Plastic Tape & Individual put in hard cardboard sleeves. Wooden packing also available on request |

Chemical Analysis For CK45

|

C (%) |

Si (%) |

Mn (%) |

P (%) |

S (%) |

|

0.42 – 0.50 |

0.40 max |

0.50 – 0.80 |

0.035 Max |

0.035 Max |

Mechanical Properties

|

Yield Stress Re (N/mm2) |

Tensile Strenght Rm (n/mm2) |

Elongation A (%) |

|

350 |

600 |

> 20% |

Induction hardened Hard chrome Plated Rods / Bars

|

Metric Size |

Dia 20mm to 300mm, Our Stock CK45 |

|

Standard Lengths |

3000mm to 8000mm |

|

Surface Hardness |

58-62 HRC |

|

Roughness |

Ra 0.07/0.20mµ |

|

Ry (Rmax): |

|

|

Chrome Plating |

950 to 1150 Hv 65 to 72 HRC |

|

Chrome Thickness |

Dia |

|

Induction Harding Depth |

Dia 18 < ? Dia 40 < ? Dia 80 < ? |

|

Tolerance |

ISO F7, F8 |

|

Circularity |

< ¼ of the f7, f8, f9 Tolerance |

|

Straightness |

Max 0.2mm/m |

|

Corrosion Resistance |

Rating 9 Achieved after 126 Hrs in neutral salt spray |

|

Packing |

In packing used cardboard tube individually and bundled |

Chemical Analysis For CK45

|

C (%) 0.42/0.50 |

Si (%) < 0.40 |

S (%) < 0.035 |

Mn (%) 0.50/0.80 |

|

P (%) < 0.035 |

Cr (%) < 0.40 |

M o (%) < 0.10 |

N i (%) < 0.40 |

Mechanical Properties

|

Range |

Yield Stress Re (n/mm2) |

Tensile Strength Rm (n/mm2) |

Elongation A (%) |

|

18 < ? < 40 |

> 400 |

630-780 |

> 18 |

|

40 < ? < 125 |

> 350 |

600-750 |

> 19 |

Chromed Deposit Characteristics

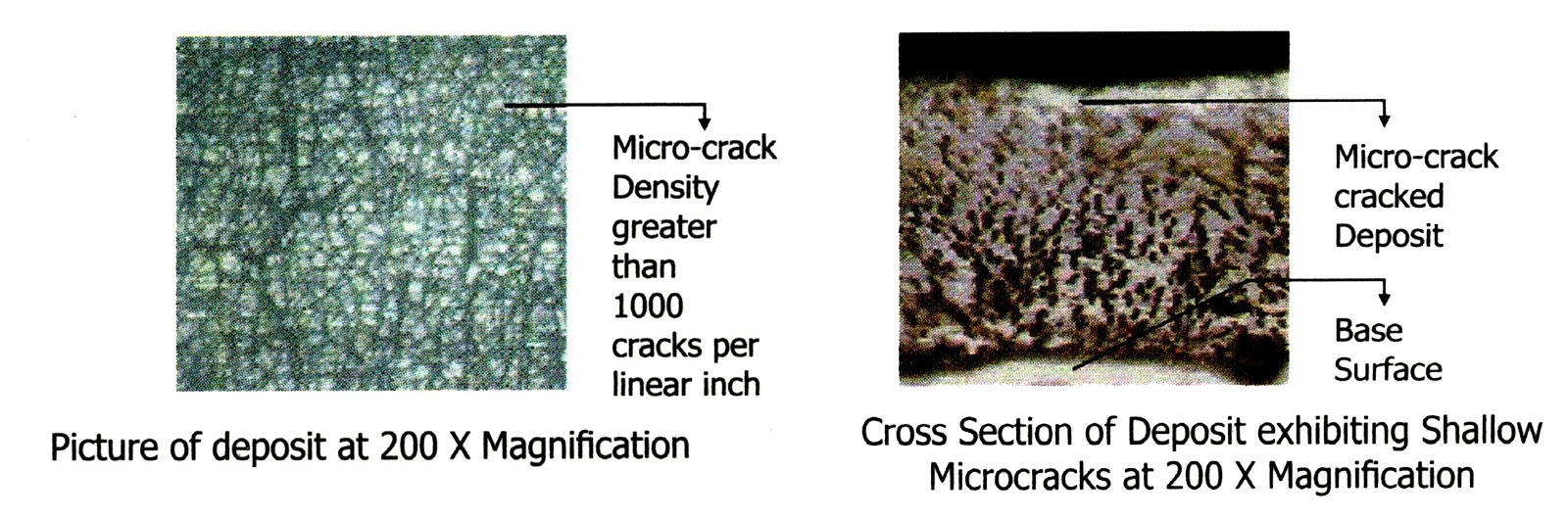

JMHSPL have the most modern plant where state-of-the-art technology is used. The process employed by us produced deposits, which are harder, smother, brighter and more durable. These deposits exhibit superior performance characteristics in term of Corrosion Resistance and Water resistance compared to deposits plated out of conventional Hard Chromium Processes. The Chromium Plating technology employed by us produces deposits with Microcrack Density (See Photo) greater than 1000 microcracks per liner inch. The actual magnified photographs of the deposits are shown. With higher Microcrack Density, The cracks are shorter and shallower, which provides superior protection to the subtracts under corrosive conditions. This holds more relevance in Hydraulic and other outdoor Applications, which are exposed to corrosive atmospheres during operation.

The Chromium oxide content in the deposit is high, which results in higher hardness of the deposit compared to conventional deposits. The hardness of the chromium deposit is greater than 900 HV (67 HRC). High oil retention in the lubricated application provides lower friction, resulting in low wear of the sliding components.