HOLLOW HARD CHROME PLATED ROD/BAR

These Tubes are chromed Plated at the outer surface and the inside of the tube is in honed condition. Mobile Application often calls for cylinders with long stroke and small profiles:- Ideal conditions for Telescopic Cylinders.

The great advantage of Telescopic Cylinders have over any other type of cylinder is their ability to provide and exceptionally long stroke from a compact initial package.

As the name infers, telescopic cylinders are constructed like a telescope. Sections of steel tubing with successfully smaller diameters nest inside each other. The larger diameter section is called the main or barrel, smaller, diameter section that move are called stages.

Because of the typical requirement the tube working in stages are required to be chrome pated from outside for their smooth movement while the barrel the largest Dia section is not chrome plated from outside.

JM Hydraulic Solutions Pvt. Ltd. is a specialist in making these Stage Tubes for Hydraulic Cylinder. These tubes are available in various sizes and diameters. Telescopic Cylinders are use in Dumpers, Waste Handling Trucks.

Standard sizes in regular use are within the range of 100mm to 200mm with maximum extrusion length of 9 meters. The working pressure is 200 bar while we also design other size as per the specific needs of our customers.

|

Metric Size |

ID40mm to 250mm |

|

Standard Lengths |

2000 to 10000mm Long |

|

Chrome Hardness |

>HV-900-1150 |

|

Ra Value |

Ra 0.2 Microns or Better |

|

Roundness |

Out of Roundness is max 1/3 of Diameter tolerance |

|

Chrome Thickness |

25 Microns Min. |

|

Tolerance |

ISO F7, F8 |

|

Circularity |

According to ISO F7, F8 |

|

Straightness |

0.1/1000 |

|

Corrosion Resistance |

Rating 10 Achieved after 120hrs in neutral salt spray |

|

Packing |

Wrap in Plastic Tape & Individual put in hard cardboard sleeves. Wooden Packing also available on request. |

Chemical Analysis For CK45

|

C% |

Si% |

Mn% |

P% |

S% |

|

0.42-0.50 |

0.40 max |

0.50-0.80 |

0.035 max |

0.035 max |

Mechanical Properties

|

Yield Stress Re (N/mm2) |

Tensile Strength Rm N (mm2) |

Elongation |

|

350 |

600 |

>20% |

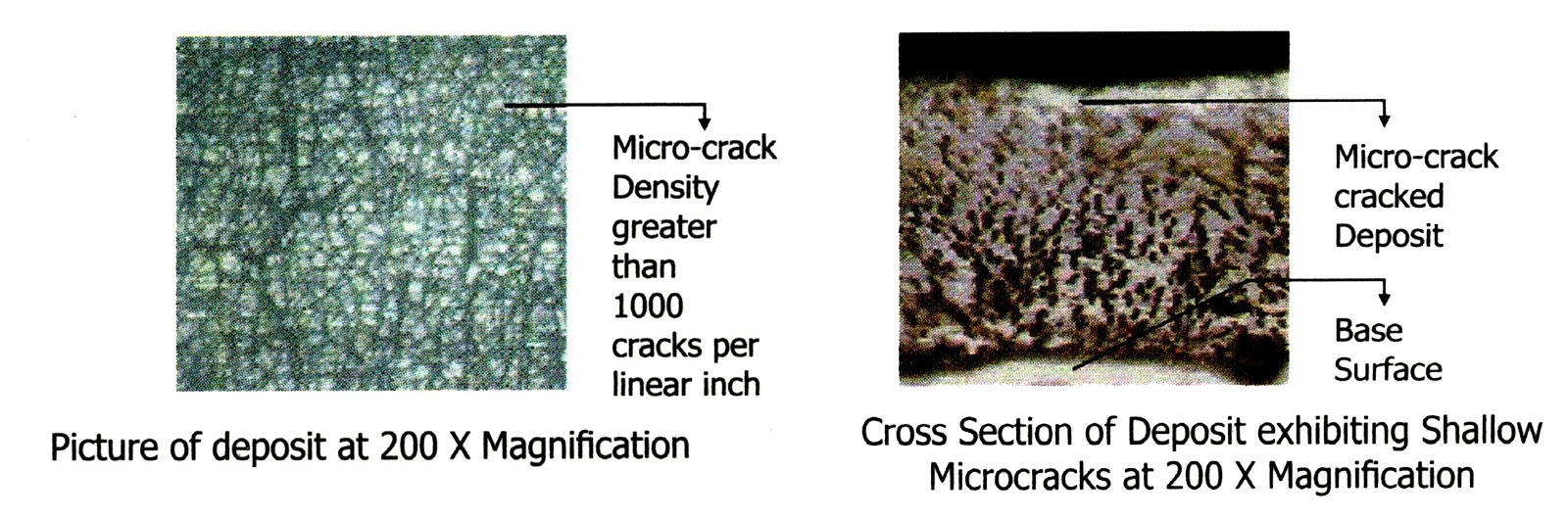

Chromed Deposit Characteristics

JMHSPL have the most modern plant where state-of-the-art technology is used. The process employed by us produced deposits, which are harder, smother, brighter and more durable. These deposits exhibit superior performance characteristics in term of Corrosion Resistance and Water resistance compared to deposits plated out of conventional Hard Chromium Processes. The Chromium Plating technology employed by us produces deposits with Microcrack Density (See Photo) greater than 1000 microcracks per liner inch. The actual magnified photographs of the deposits are shown. With higher Microcrack Density, The cracks are shorter and shallower, which provides superior protection to the subtracts under corrosive conditions. This holds more relevance in Hydraulic and other outdoor Applications, which are exposed to corrosive atmospheres during operation.

The Chromium oxide content in the deposit is high, which results in higher hardness of the deposit compared to conventional deposits. The hardness of the chromium deposit is greater than 900 HV (67 HRC). High oil retention in the lubricated application provides lower friction, resulting in low wear of the sliding components.